Jump to:

Plenty of garden sheds look the part but fall short when put to use for woodworking. They aren’t built to take the weight or layout demands, so what you need is a model that is. Here’s a breakdown of what works for a woodworking shed.

Best Features for a Woodworking Shed

A wooden shed made for woodworking needs to handle more than storage. It should be:

Large with open space

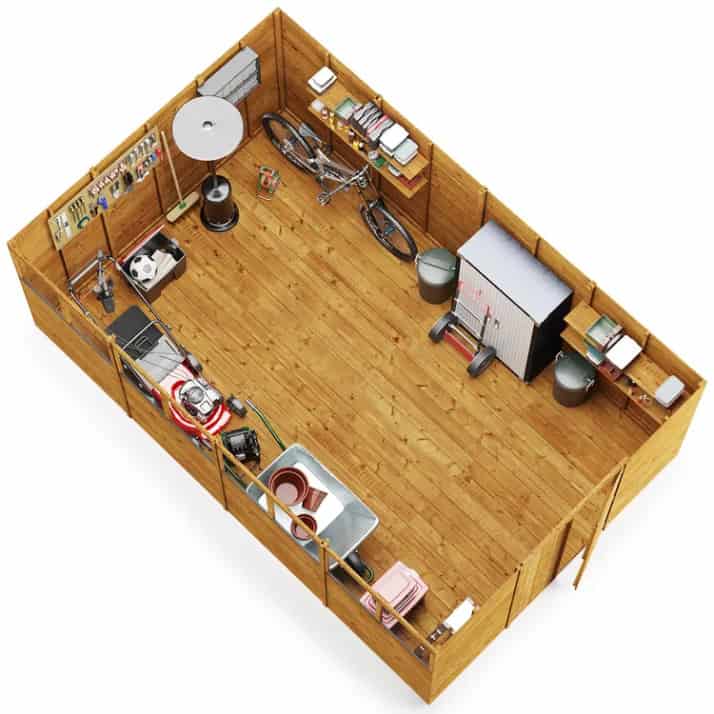

A woodworking shed needs to give you a clear space to move, work, and store timber and tools. Or else, there won’t be enough room once the bench, saw, storage, and timber piles are inside.

Around 10x8ft is a great starting point, but you can always go for 12x10ft or bigger. This should give you enough floor area, depending on how you lay out your setup.

Thick, durable walls or cladding

For a woodworking shed, go for tongue and groove cladding. These are made from interlocking boards that form a solid, tight fit. They’re stronger than overlap, better at keeping the cold out, and can take weight, knocks, and regular use.

11mm thickness as a standard is up to the job—but the thicker, the better. Many wooden sheds come with upgrade options from 19mm to 44mm and above. Remember, anything thinner will start to flex once you load it up.

Tall with high ceilings

A shed with a high ceiling means more headroom to move and better airflow. At least 6.5 to 7 feet of internal height is your best bet, with either apex or reverse apex roof style. Both give you that extra clearance in the middle, which comes in handy when:

- mounting overhead racks

- installing task lighting

- storing timber vertically

It also gives you the height needed to work with sheet materials, long planks, or tall cabinets.

Solid and level underfoot

The floor needs to be strong, flat, and steady. Go for concrete, treated timber joists, or 18mm tongue and groove boards. These can take the weight of benches, saws, and timber stacks without shifting or sagging.

Any flex or slope makes it harder to cut accurately, keep tools steady, or build square. Thin panels or chipboard won’t hold up either; they wear out fast and struggle with heavy loads.

Built with windows

A suitable woodworking shed has side windows for steady daylight where you need it most. Skylights are also useful, though they aren’t common for wooden sheds, but you can find them in plastic sheds.

Natural light makes detailed work easier. You’ll spot rough cuts, grain direction, and surface marks faster than under weak lighting. And while this helps during the day, you’ll still want to add a few lights so you can keep working into the evening.

BillyOh Expert Tongue and Groove Apex Workshop

The BillyOh Expert T&G Apex Workshop ticks all the boxes for an ideal woodworking shed. Sizes start at 12×8, with larger options like 16×10 for more floor space.

It’s built with 11mm T&G cladding and strong 28x28mm framing for added stability. The apex roof gives you a tall ceiling for overhead storage and easier movement.

The floor is also tongue and groove, with a 19mm upgrade available for heavier use. Side window panels let in natural light, and the 4-foot-wide double doors make access easy.

It’s a shed that gives you the space, structure, and features to get started with woodworking. You’ll also find more styles across our full range of garden workshops, including log cabin sheds.

Up next on your reading list: Everything You Need in a Garden DIY Workshop