Jump to:

When investing in a garden shed or a summer house, tongue and groove (T&G) cladding is a strong contender. If you’re in the market for one, you may have come across terms like “tongues,” “grooves,” and “shiplap”. This may leave you wondering what they mean, so we’re here to help!

Here’s our ultimate guide and FAQs to give you ideas and help you make informed choices.

What is Tongue and Groove Cladding?

Tongue and groove cladding, or T&G, is a special wooden board used in building wooden structures. Normally, when you put wooden boards together, you need to use fasteners to keep them in place. But T&G panels are designed to slot into each other snugly without needing any extra nails or glue. It’s like putting puzzle pieces together; they just fit perfectly without nails to hold them in place.

When we talk about the construction, it’s all about the clever way these wooden panels are made to fit together. This clever method is called “tongue-and-groove.”

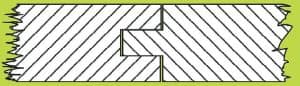

Now, imagine each wooden panel having two special parts: 1.) a tongue, which sticks out a bit, and 2.) a groove, which is like a slot for the tongue to slide into. These tongue and groove parts are placed at the edges of the panel, one at the top and one at the bottom. This setup lets them lock into each other neatly, making it easy to connect one T&G board to another without any gaps.

The picture shows a cutaway view of a T&Gjoint, demonstrating how two panels fit together.

In a shed, the panels are fitted vertically, with the groove fitting to the tongue of the panel below. Further panels are stacked on each other to form a wall, roof, floor, or another wood surface.

What is cladding?

Cladding is a layer of material that gives a building protective skin. It improves a building’s insulation, weather resistance, and appearance.

You can put cladding on the outside or inside of a building, depending on how you want it to look. It’s attached to the building horizontally or vertically to keep it insulated. This is what gives sheds and other garden buildings their unique, cosy style.

Cladding can be made from many different materials and assembled in different ways. How the pieces of cladding fit together is what we call its ‘profile.’

Outdoor structures often use different materials and construction methods for their outer layers. Among the common types are overlap, shiplap, and tongue-and-groove joinery.

Are Shiplap and Tongue and Groove The Same?

In technical terms, the shiplap profile is a form of tongue-and-groove joint. While shiplap features an ‘over-and-under’ rabbet, T&G utilises interlocking recesses. This means that shiplap and tongue and groove share a similar aesthetic.

Their joint creates a smooth exterior without visible gaps. Shiplap’s V-groove design, however, provides superior runoff. This makes it potentially more suitable for larger-scale constructions. The question is – which is better?

The key differences boil down to water runoff and resistance, although minimal. Shiplap’s longer ‘lip’ means that the area of the seal is extended. This, in turn, might offer better protection against moisture and water ingress.

Shiplap also deals slightly better with runoff. Yet, with this comes a higher price tag, offering only marginal improvements over T&G cladding. So, unless you’re building a shed next to a lighthouse, T&G delivers more than sufficient protection.

How Do Overlap and Tongue and Groove Differ?

| Tongue and Groove | Overlap Cladding | |

| Appearance | Creates a smooth and modern finish for any garden building. | Provides an outdated slatted finish – not preferable for contemporary sheds. |

| Security | Flat surface and no-grip exterior walls mean it is nearly impossible to break cladding apart. Extremely secure. | Exposed board ends and connecting nails make cladding easy to break and vulnerable. |

| Cost | Specially constructed boards are expensive to build. High costs. | Versatile, able to use any type of wooden boarding. Cheap to buy and very cost-effective. |

| Assembly | Easy-slide in assembly with no tools or knowledge required. | Manual assembly requires tools and knowledge of how to create proper overlaps. |

| Space between boards | Next to no space between the boards. Repels draughts and water while providing insulation. | Gaps are likely after construction and can form over time. Lets in wind and rain, susceptible to water damage. |

| Strength | Internal connections create a strong structural spine. | Boards are nailed together rather than connected so provide little strength. |

Tongue and Groove Cladding and Weather

In this section, we’ll delve into how T&G cladding handles various weather conditions.

Will tongue and groove warp?

With its tight seal and resistance to rot, T&G timber is unlikely to warp. This is thanks to its weather resistance and ability to expand in different climates.

However, it’s essential to apply shed stain or treatment to maintain its integrity. You can also opt for pressure-treated T&G timber for added protection.

Are tongue and groove waterproof?

T&G cladding serves as a robust barrier against water damage for your garden shed. Its construction ensures water can’t seep into your shed’s wood or interior. This water-resistant feature also minimises the risk of rot, further enhancing the durability.

Why Invest in Tongue and Groove Sheds?

Looking for a high-quality, weather-resistant, durable, and reasonably priced shed? A tongue and groove shed is your answer. Its T&G construction is perfect for storing valuable tools, garden furniture, and more. Unlike overlapped panelling, the interlocking panels make it much harder to break into. Plus, it offers better protection against water, making for a well-insulated shed.

With this cladding, the shed can achieve that classic look with a clean, modern design. The boards also contract with changes in the weather. This makes them less likely to rot or wrap, keeping the structure in pristine condition for years. Their durability is why they’re popular as a flooring material, able to handle heavy foot traffic.

Round-up

Tongue and Groove cladding is a wood covering that fits together without gaps. It’s great for keeping out bad weather and making buildings look nice. Additionally, T&G cladding lasts a long time without bending or warping. You can use it inside or outside for sheds, floors, or decking. Just remember to take care of it properly; it will keep your building strong and looking good for a long time!

Explore Garden Buidlings Direct for a range of tongue and groove garden sheds. Next on your reading list: What Is Pressure Treatment and How Does It Protect Wood?

Shop Reverse Apex Workshop