Jump to:

Cladding is the material that covers your garden shed and sits against the frame. Some people add an extra layer for insulation, but it usually refers to the main wall material and how the shed is built.

With wooden sheds, cladding comes in three styles. This guide breaks down each to help you find the best fit for your outdoor storage and workshop needs.

Common Types of Wooden Shed Cladding

Shiplap Cladding

Shiplap is a type of wooden shed cladding. Each board has an L-shaped edge, so one can partly overlap the next. When two boards meet, the rabbet on one fits snugly over the rabbet on the other.

This ‘locked’ detail maintains a flat and smooth surface. The boards also overlap in a way that creates a waterproof frontage that ensures water runs off. A good way to picture it is like roof tiles. Each board overlaps the next to keep out rain, except that this results in a completely vertical wall with no protruding edges.

Go for shiplap cladding if you want a shed with a clean exterior and good weather resistance. Not to mention, it comes at a low price.

Tongue and Groove Shed Cladding

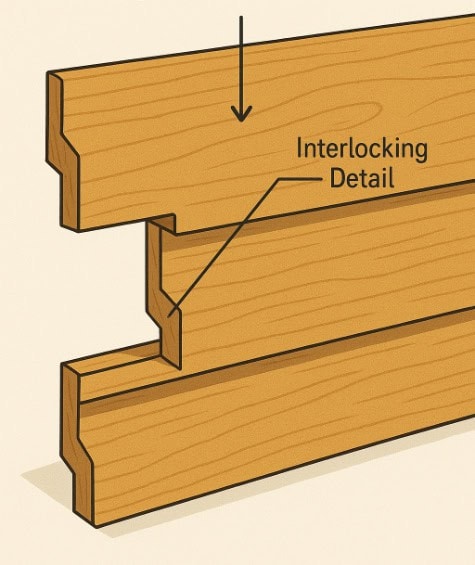

Tongue and groove (T&G) is another common type of wooden shed cladding. Each board has a tongue on one side and a groove on the other, linking edge to edge.

Unlike shiplap, T&G boards don’t overlap. Instead, each board ‘plugs into’ the next. The boards join to form a tight, flat surface with no visible gaps. It’s like putting puzzle pieces together.

But don’t worry; you don’t normally have to piece every single board together yourself. T&G shed kits generally come with pre-manufactured wall panels, where this is already done for you.

The end result gives the shed a strong, weather-resistant, and polished look. This makes it ideal for higher-end wooden garden storage, though it does cost more. Our T&G range gives you better value for your money:

Browse Self-Assembly Shed Kits

Overlap Cladding

Overlap wooden shed cladding is a method where boards are laid diagonally. Each overlaps the one beneath it, hence the name.

The overlapping boards help the shed cope better with the weather. Rain, snow, and wind are kept out, and moisture doesn’t get the chance to seep inside.

You’ll notice the seams between the boards. They give it a more traditional look while helping to keep water out.

A Quick Comparison

Shiplap vs Tongue and Groove Cladding

Both give you a neat finish and good weather protection, but they’re put together in different ways. With shiplap, the boards overlap, which helps rain run off and gives the wood some space to move when it needs to. Tongue and groove boards, on the other hand, lock together to create a stronger wall with a better seal. Shiplap is thinner overall, whereas tongue and groove maintains a consistent thickness from the top to the bottom of each board.

If you want a cleaner look with extra strength, tongue and groove has the edge.

Overlap vs Tongue and Groove Cladding

Overlap sheds are budget-friendly and perfect for first-time owners. They’re not as strong as other options, but they’re a good starting point if you don’t need anything heavy-duty.

Tongue and groove sheds are a step up. They do cost more, but you’re getting a shed that will stand up better to the weather and last for years. If you want something you won’t have to replace too soon, tongue and groove is the better bet.

Insulation in Wooden Shed Cladding

Overlap cladding does offer weather protection, but the boards are thinner, around 7mm. That results in small gaps where air can get through. This means it won’t keep heat in as well as thicker options.

Shiplap cladding is a bit thicker than overlap cladding, but it has thinner sections due to its shape. The groove-fitted boards improve insulation compared to an overlap. Yet, it’s still not as good as thicker options.

Tongue and groove cladding comes in straight boards of consistent thicknesses, available from 11mm up to 15mm. The thicker boards and tight joints help keep out drafts and moisture. The thicker the boards, the better the shed will hold heat, making T&G the best option for insulation.

Learn more:

Do You Need an Air Gap for Shed Insulation

This also applies to log cabin sheds if you’re looking at other waterproof wooden storage options. They use tongue and groove joints, but the boards are longer than in panel sheds, so you assemble them one log at a time.

Log cabins can be up to 44mm thick. This extra thickness keeps them warmer and lets the walls hold more weight than a standard wooden shed.

Still shopping for your new shed? Check out our quality selections and the guide below: