Jump to:

The term ‘pressure treated’ or ‘pressure treatment’ may be a phrase you hear banded about a lot. As a crucial aspect of wood preservation, it safeguards garden structures such as:

In this guide, we demystify the intricacies of pressure treatment, uncovering its significance. Our aim is to give you all the information you need to make smart decisions. So, join us as we go through all the pressure treatment-based questions. Keep reading!

The Science of Wood Preservation

Wood, a natural material, is inherently vulnerable to rot, decay, and structural changes. While it remains part of a tree, it’s resilient due to the tree’s rooted stability. However, once transformed into planks, wood becomes susceptible to warping or bowing. This phenomenon is noticeable in everyday wooden items. For one, a once flat chopping board may warp after absorbing water during washing. However, wet wood attracts insects and bugs, especially woodlice. These pesky little creatures thrive in the damp, dark conditions.

Yet, with proper care, these issues can be mitigated. Understanding the vulnerabilities of wood allows for informed measures. Cue pressure treatment. This approach preserves the integrity of wood against the forces of nature.

The Power of Copper in Pressure Treatment

Copper has become crucial in preserving wood since the mid-2000s, transforming pressure treatment. This magical metal doesn’t just halt the growth of fungi and microbes. It also acts as a formidable barrier against mould and mildew. Its power lies in oxidising enzymes, lipids, and proteins, making them harmful. This creates an unwelcome environment for pests like termites. In return, it effectively keeps them away from thriving around the treated wood.

Copper, a key element in pressure treatment, protects wood from fungi and pests. It transforms the process into a potent shield, acting as a power defender for wood structures.

Introducing Wood Preservers

Wood preservation, a time-honoured practice spanning centuries, involves the use of wood preservers. These come in tins and can be applied like paint — an alternative to pressure treatment. They provide an additional layer of protection against environmental factors and decay. A practical way to enhance the longevity of wooden garden rooms.

For those opting out of pressure treatment, wood treatment is necessary at least once a year. But remember that it won’t be as resilient as wood treated with pressure treatment. Top tip: Is your goal both aesthetic enhancement and structural protection? If so, combine a shed stain with a wood preserver for your timber shed.

The industrial precision involved in pressure treatment is challenging to replicate at home. Hence, we strongly recommend choosing pressure treatment when acquiring any of our buildings. Not only this saves you from the annual hassle of self-treatment. But it also ensures a level of protection and durability that manual methods can’t match.

Understanding Tanalising

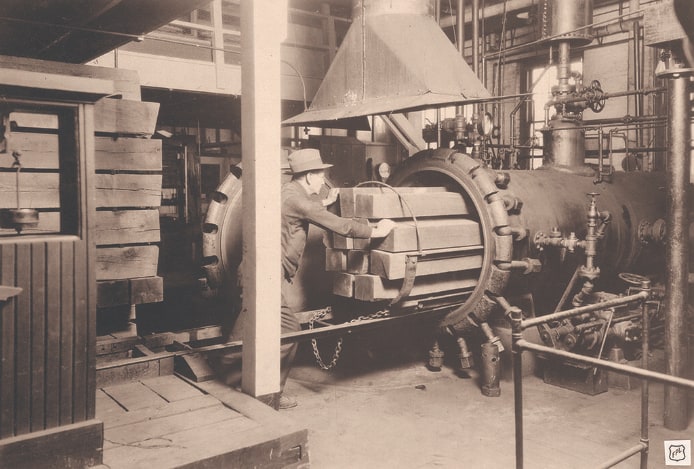

Pressure-treating, also called ‘tanalising,’ uses a special solution called ‘Tanalith E’. Note that different companies may use different solutions for preserving wood.

The process happens in tall, flat vats where batches of thin planks are bundled. The vats are horizontal for easy access. After sealing, a vacuum removes air, and Tanalith E is poured in. Another vacuum increases pressure, pushing the solution deep into the wood. This meticulous process ensures chemicals penetrate the wood grain thoroughly. It surpasses the effectiveness of simple paint-on preservers in return. Overall, it offers reliable, long-lasting protections for outdoor structures.

Insights into Pressure Treatment

Pressure-treated wood undergoes a transformation. It displays a natural green hue due to the copper in the solution reacting with the air. Over time, this tint fades to the original sandy-brown colour of natural softwood. This assures that the wood is not mouldy but simply evolving.

After treatment, the wood requires considerable time to dry thoroughly. At Garden Buildings Direct, a vacuum wrap is occasionally applied before complete drying. This leads to a misconception of rotting upon delivery. However, the green or wet appearance actually enhances the wood’s weather resilience.

Pressure treatment proves to be a robust defence against rot. Moreover, this extends the anti-rot guarantee from ten to fifteen years. Take, for instance, our very own BillyOh Switch Tongue and Groove Pent Shed. It now comes with pressure treatment as a standard feature.

Painting a Pressure-Treated Shed

Can I paint a pressure-treated shed? Yes, you can paint or stain one to customise its appearance beyond the natural colouring. However, a crucial consideration is the moisture content within the wood.

Make sure the wood is completely dry before doing so. If the wood is damp, oil-based paints won’t stick well, and water-based paints won’t absorb due to moisture. Allowing the wood to dry thoroughly ensures the paint adheres properly. Most importantly, this will result in a durable and visually pleasing finish.

Round-up

We trust this guide provided valuable insights into the benefits of pressure treatment. Almost all our garden buildings offer this protective process. Simply check the ‘Select Treatment’ section on your chosen product’s page. For further exploration, delve into our ‘Advance Garden Shed Guide.’

Whether it’s an outdoor shed or a workshop building, your wooden investment is not just a choice. It’s a commitment to longevity. Thanks for joining us on this journey!